Surface Mount PCB: The Evolution of Compact Electronics

Surface Mount PCB: The Evolution of Compact Electronics

Blog Article

In today’s dynamic electronics Surface Mount PCB (Printed Circuit Board) emerged as a game changer in technology, and changed the way we design, manufacture and use electronic devices This compact and efficient solution from smartphone and laptop to myriad medical devices and aerospace components -Opening the way for miniaturization and increased efficiency of consumer and industrial products.

Introduction to Surface Mount PCB

The main advantages of SMT PCBs are their compact design and space efficiency. By eliminating the need for larger port holes, SMT components can be placed much closer together, significantly reducing the overall size and weight of the final product, allowing smaller electronic devices, a portable and beautiful.

SMT PCB technology development

The origins of surface mounting technology can be traced back to the 1960s, when the concept was first introduced in response to the growing demand for lighter, more packed electronic components but by the 1980s, the rapid growth of the electronics industry and the need for high-quality manufacturing led to their widespread acceptance

Early development

In the early stages of SMT PCB, this technology faced many challenges, including limited availability of suitable materials and difficulties in obtaining reliable solder connections.

Early development

In the early stages of SMT PCB, this technology faced many challenges, such as the limited availability of suitable materials and difficulties in obtaining reliable solder connections

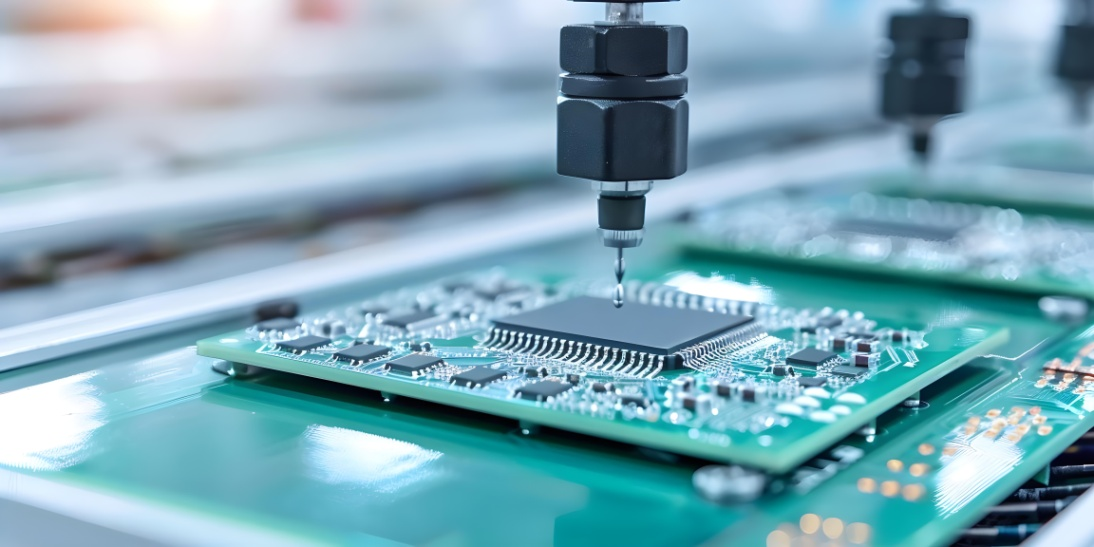

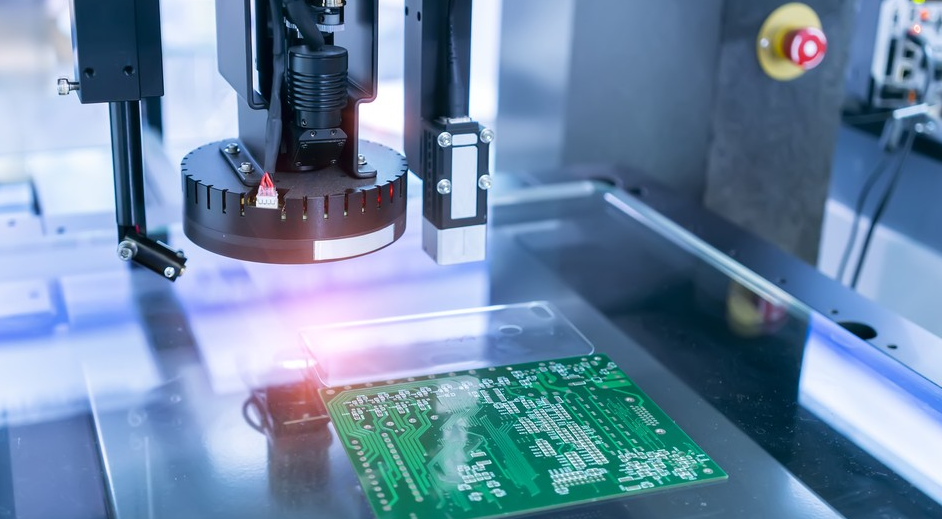

Increased automated assembly

As the technology matured, the manufacturing process changed with the introduction of surface mounting machines (SMAs). These specialized machines, known as removal and installation machines, can precisely mount and solder the SMT components onto the PCB, greatly improving the speed and accuracy of manufacturing when compare with manual collection

The advent of SMA tools, coupled with the continued refinement of SMT component layouts, enabled manufacturers to achieve unprecedented miniaturization and integration, and led to the continued adoption of SMT PCBs in a wide range of industries

Improvements in materials and processes

In addition to the development of assembly techniques, the materials and techniques used to manufacture SMT PCBs have greatly improved All innovations in solder alloys, surface finishes and substrate materials have contributed to the reliability, efficiency and cost effectiveness of SMT PCBs have improved

For example, the introduction of lead-free solder alloys in response to environmental concerns has led to the development of new soldering techniques and component designs to ensure reliable connections to SMT PCBs with substrate materials advanced features such as high-frequency laminates and flexible circuits -extended to specialized areas such as air and space.

Advantages of SMT PCB

The widespread adoption of SMT PCB technology can be attributed to its many advantages, making it a very attractive choice for a wide range of electronic applications

Cost effectiveness

The use of automated assembly and manufacturing processes in the manufacture of SMT PCBs made the technology more cost-effective compared to traditional through-hole methods The increased production of SMT parts and assembly lines increased operating costs all are reduced, so that SMT -PCBs have become an economical choice for a wide range of applications

Developing confidence

SMT PCBs have also demonstrated improved reliability over their hollow counterparts. Solder joints formed between SMT components and PCBs are typically rigid and insensitive to mechanical stress, vibration and thermal cycling, prolonging the life of the final product

Increased conversion

The versatility of SMT PCBs extends beyond their compact design and practical advantages. The ability to deliver components on both sides of the board, as well as the increased design deliverability of SMT, has enabled engineers to create complex and sophisticated circuit designs, expanding the applicability of this technology greater than

Using SMT PCBs

The versatility of SMT PCB technology has made it a ubiquitous choice in a wide range of industries and applications, from consumer electronics to industrial medical devices.

Electronic Equipment

The most prominent application for SMT PCBs can be found in the consumer electronics sector, where the demand for small, portable and feature-rich devices continues to grow Smartphones, tablets, laptops, and personal electronics all types use SMT to achieve their compact and efficient structure. they rely on PCBs.

Industrial and Automotive Electronics

In addition to consumer electronics applications, SMT PCBs have also found extensive applications in the industrial and automotive industries, where there is a need for reliable, compact and efficient electronic devices From industrial system applications up to process equipment to advanced automotive electronics

Medical and Space Electronics

The medical and aerospace industries have also recognized the benefits of SMT PCBs with strong demands for reliability, accuracy and miniaturization SMT PCBs play a key role in the safety, reliability and performance of these key electronic devices, from diagnostics to medical cameras to avionics and satellite systems.

Telecommunications and Networks

The telecom and networking industries have been early adopters of SMT PCB technology, as the demand for fast, high density, compact electronic components in these industries has been the driving force behind SMT PCBs making modern connectivity from router switches to base station and satellite so communication -became central to the infrastructure powering the network.

Advances in SMT PCB technology

As the electronics industry continues to evolve, PCB surface mount technology is also constantly evolving to keep pace with the increasing demands of modern electronics

Miniaturization and fine-pitch parts

One of the most important advances in SMT PCB technology is the continued miniaturization of components and finer design.

The use of micro-scale and nano-scale materials, such as the 0201 (0.25 x 0.125 mm) and 01005 (0.4 x 0.2 mm) packages push the limits of SMT PCB design, enabling reliable - Special fabrication techniques and equipment are needed to ensure connectivity and performance.

Multi-layered and flexible design

Another area of progress in SMT PCB technology is the development of multilayer and flexible designs. Multi-layer PCBs allow more robust circuit design, including additional copper layers for power distribution, ground plane and advanced routing capabilities

However, flexible PCBs have enabled the integration of electronic devices on non-flat and curved surfaces, expanding the range of possible design applications from wearable devices to compatible electronic devices on.

High-frequency and high-speed circuits

As the world demand for faster and powerful electronics grew, so did SMT PCB technology to sustain high-frequency and high-speed circuit systems with specialized components such as the use of strong, low-loss gas-tight containers improved. By using trace-routing and impedance control techniques, SMT PCBs were enabled to handle signals in the ranges of GHz.

These are somewhat closer to the areas of telecommunication, radar applications, and high-speed data transfer where sheer need for the efficient and dependable high-speed signal transfer is paramount.

undefined

There has been a concept of embedded components developed in order to have much better improvements in both the integration and functionality of SMT PCBs. In this respect, this method dictates that passive elements like capacitors and resistors have to be integrated directly into the substrate of a PCB, thus minimizing the number of components and the board size.

Further, the integration of Integrated Circuits, power management modules, and active components into compact and effective electronic systems in PCB layers will be possible; this is known as embedded active components or embedded die technology

3D printing and Additive Manufacturing

The new additive manufacturing and 3D printing technologies are also attacking the SMT PCB landscape. Printing techniques like inkjet or aerosol-jet printing allow directly depositing conductive traces and components onto soft or hard substrates, thus enabling custom on-demand fabrication of printed circuit boards in a very straightforward manner without the need to adopt complex fabrication processes, as in traditional methods.

It offers freedom of design, quick prototyping, and integration of new materials and components that will expand the technological possibilities of SMT PCBs even further. Environmental sustainability and environmentally friendly practices

As global attention to the environment increases, the SMT PCB industry is also working to address the environmental impact of its manufacturing processes and products This has led to more environmentally friendly products, such as lead-free solder alloys, halogen free and laminate, reduced waste, . Implementing sustainable building practices, including energy efficiency and recycling policies

Adopting these environmentally friendly practices not only helps reduce the environmental footprint of SMTs and PCBs, but coexists with green electronics the growing demand for regularity also meets

Challenges and prospects

While the success of SMT PCB technology is undeniable, the industry continues to constantly face challenges and evolving trends that will shape its future growth.

Miniaturization and increased complexity

The relentless demand for smaller, more powerful, multi-core electronic devices has created an ever-increasing demand for further miniaturization of SMT PCBs This in turn has led to the development of more robust components, larger, more beautiful volumes and advanced collection methods to accommodate increasing on-board capacity

Heat Consumption and power dissipation

As electronic devices become smaller and more powerful, the challenge of controlling heat dissipation and thermal efficiency has become a major concern for SMT PCB design Sophisticated cooling solutions such as thermal circuits are being developed , advanced heaters, and specialized materials solve these heating problems.

Environmental sustainability

Enhancement of consciousness of the environment has also been felt in the SMT PCB industry of recent, to go for lead-free solder alloys, looking at how it can get better substitutes that are less hazardous to the environment and also look at how the recycling and disposal of the SMT PCBs can be done in a way that will not significantly harm the environment.

Improvement of the methods of collection

Optimisations to the kinds of mass retail manufacturing automated surface assembly equipment etc, particularly high-speed pick-and-place machines and vision systems continue to stimulate more expansion for SMT in the fast and precise production of printed circuit boards.

In the rapidly changing electronics industry, upcoming technologies and trends are likely to impact SMT PCB design and manufacturing in the near future. For instance, flexible electronics, printed and organic electronics, and 3D printed materials can introduce a completely different set of opportunities and challenges for SMT PCB technology.

Advancements in Materials and Processes

The most significant and very important area for further development is in continuous improvement in materials and designs SMT PCBs of SMT PCBs, including the investigating of new substrate materials like thermoplastics and composites with click here high performance, as well as upgrading the existing materials to gain improved electrical, thermal, and mechanical characteristics.

In addition, advances in additive manufacturing methods, such as 3D printing and direct printing, are making the processes involved in the manufacture of PCBs more versatile and scalable. It is now set to multiply the variations in design, of which the greatest will be to a quicker turnaround.

Improved functionality and integration

As long as there are demands for miniaturization at the same time as increasing functionality of electronics, the development of SMT PCB technology must strive for higher function and integration with embedded systems, system-in-package components, soaring advanced sensors, and energy storage and management, in which the PCB may also overhead integration.

The concept of being able to package many functions into a compact step discretely would be the key to advancement of next generation wearables and IoT devices, and other portable or aerospace electronics used.

Smart and adaptive printed circuit board design

Such an intelligent design would go a long way in implementing flexible PCB designs, that would respond to the dynamic change in the specifics and needs, the physical conditions, and the commercial environment.

That could lead to more complex, dynamic and self-sufficient electronic systems whose functioning is being controlled and enhanced all the time hence achieving the reliability and durability of products that use SMT PCBs’ high.

Implementing such strategy, the SMT PCB industry will contribute to the development of circular economy that moderates the whole-life environmental effect of electronics. Smt pcb technology has been one of the most important aspect in the development of modern day electronics whether is consumer electronics or industrial and chemical applications.

Coaching the emergent technologies and advancing through the continuous challenges, the SMT PCB industry still keeps the right of being an important part of the development of electronic devices and the related systems in the future, through which, the way we interact with the world around is going to be shifted significantly.